Alcraft Motor Company has adopted a ground-breaking new chassis structure technology thanks to a partnership with innovative British high-performance design and engineering solutions provider KW Special Projects.

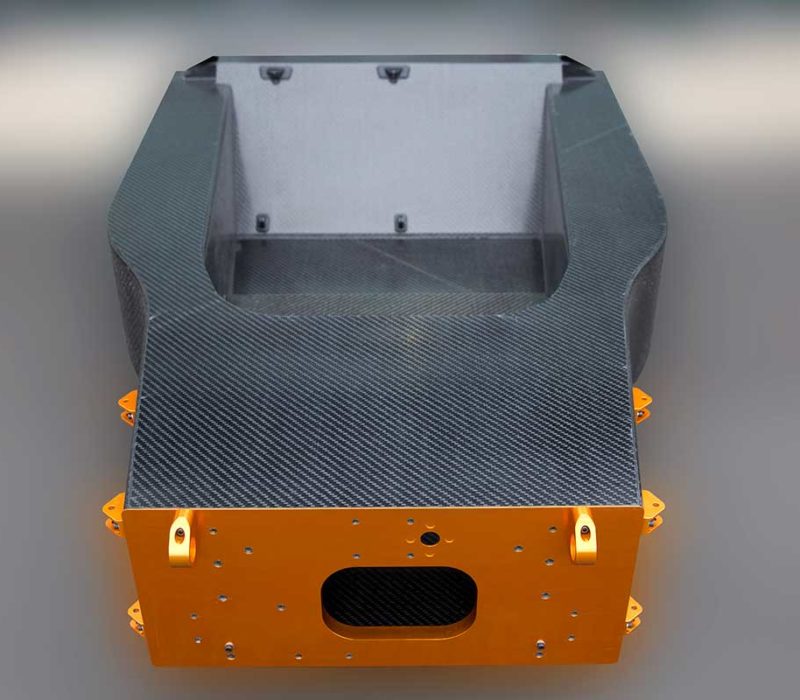

Based in Brackley in the heart of the UK’s Motorsport Valley and the Silverstone technology cluster, KWSP has a high level of expertise in digital manufacturing together with extensive experience in composites and light-weighting, and has developed a potentially transformative carbon composite vehicle platform, ToPCaT.

The technology is targeted at achieving automotive manufacturing costs targets and recyclability requirements yet retains the advantages of low weight, high strength, stiffness and thermal management of traditional composites.

The ToPCaT chassis has already been developed into a motor sport demonstrator but, with the Alcraft partnership, for the first time it can now be designed into the application of a road car, the Alcraft GT.

“We’re thrilled to be working with KWSP,” says Alcraft Motor Company founder and chairman David Alcraft. “They are leaders in digital manufacturing technology, which will become increasingly important for light weighting, cost reduction and sustainability. ToPCaT is ideally suited to the cars we’re developing and we’re very excited to be able to share in one another’s vision.”

Alcraft will continue to work with its other partners, including Delta Motorsport, to develop key areas of the GT including powertrain.